No Room for Delay: Preventing a Costly Line Stop

Preventing downtime through rapid action and precise coordination

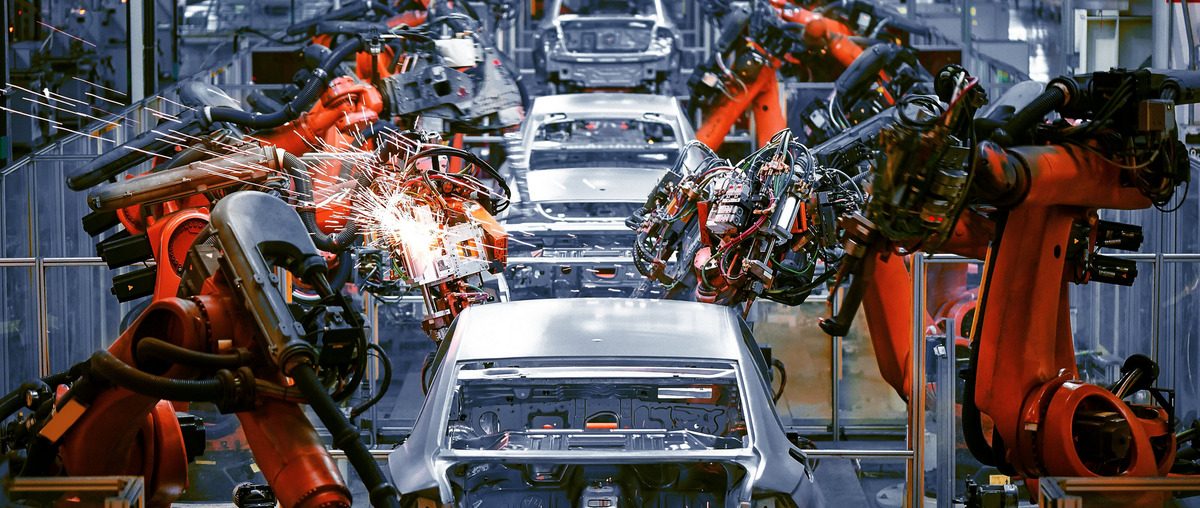

When time-critical shipments are delayed, production lines can grind to a halt – costing businesses hundreds of thousands in lost output. This case study shows how Freightline’s swift intervention, trusted network, and seamless coordination kept our client’s manufacturing line running under extreme pressure.

The Challenge

A Critical Delay with Just Hours of Stock Left

A leading specialist in powertrain solutions scheduled a groupage shipment of essential products from Spain to the West Midlands, with delivery planned within a few days. However, an unexpected delay put the client’s production at immediate risk. With only half a day’s worth of components left, a complete line halt was imminent – a disruption that could cost over £100,000 per day.

In the automotive sector, production schedules run on time with no room for error; any disruption can have a significant impact across production lines and the supply chain. With no alternative stock available and deadlines fast approaching, the client was facing a high-pressure situation where every hour mattered. Delays at this stage aren’t just inconvenient – they are critical.

Our Strategy

Intercepting the Shipment and Regaining Control

With time running out and over £100k of production value at risk, our team took immediate action. We identified the shipment’s exact location within the groupage network and arranged for a dedicated vehicle to retrieve from the holding warehouse.

Thanks to our direct access to multiple carrier networks and real-time communication with warehouse staff, we secured an urgent release and coordinated a priority handover. The shipment was quickly transferred to a dedicated van, eliminating the risks tied to shared routing and delays.

This was more than just speed; it was about regaining control at a critical moment. By intervening mid-transit, we ensured production continuity and delivered clarity when it mattered most. Our decisive action demonstrated our ability to respond under pressure and our commitment to protecting our clients from costly disruptions. Where others might wait for the network to resolve delays, Freightline steps in to take control and keep supply chains moving.

Our Impact

Rapid delivery avoided production disruption.

As a result, the goods arrived early and were offloaded in time for immediate use. This early arrival not only maintained continuous output but also allowed the client to plan their production schedule more effectively, avoiding operational downtime and financial loss.

In a situation where every hour mattered, our prompt intervention ensured business continuity and demonstrated Freightline’s ability to act decisively under pressure.

When delays threaten production, there is no room for hesitation. Intercepting a shipment mid-transit demands speed, accuracy, and dependable communication. At Freightline, we view every challenge as an opportunity to improve – resolving issues before they escalate and ensuring our clients never have to pause what matters most.

Why Our Approach Works

- Swift Escalation Handling – When a transit delay threatened production, we promptly identified the risk and intervened with a quicker, dedicated solution.

- Flexible Network Access – Our extensive pool of approved carriers enabled us to source a dedicated van at short notice, preventing any further delays.

- Production-first Mindset – With a line stop imminent, we prioritise speed, clarity, and proactive communication to protect the client’s operations.

- End-to-end coordination – From warehouse collection to swift delivery, we supervised every phase for a seamless result.

The Freightline Difference

Avoiding a costly production halt required more than just speed – it demanded precision. By intervening before the delay escalated, Freightline ensured continuity for the client’s manufacturing line and prevented significant financial losses. Our ability to act swiftly, communicate clearly, and deliver punctually meant the client could stay focused on operations without disruption.

Conclusion

Freightline’s rapid coordination, proactive communication and 24/7 availability turned a potential shutdown into a success story, protecting our client from six-figure losses and keeping production moving without a single missed beat. In an industry where every hour of downtime can result in financial and reputational damage. At Freightline, our ability to deliver speed and reliability is what keeps critical production lines moving.

The success of this intervention highlights the importance of dedicated customer support in today’s automotive sector. Our expertise, around-the-clock support, and proactive planning ensure production never comes to a halt. That’s why leading manufacturers continue to trust Freightline to protect their supply chain when it matters most.

Experience Professional International Solutions

Ready to see how we can simplify your complex logistics requirements?

Call us today on

+44 (0) 1926 290 222

Email [email protected]

Visit our website www.freightlinecarriers.co.uk